| Address |

140-1 Aza Goboyachi, Natsuta, Isawa, Oshu-shi, Iwate-ken 023-0401, Japan

|

| Telephone |

+81-197-46-2141 (main switchboard) |

| FAX |

+81-197-46-2143 |

| Established |

April 1980 |

| Capital |

JPY 18.5 million |

| Site Area |

9,000m² |

| Total Floor Area |

3,700m² |

| No. of Employees |

70 |

| ISO 9001 |

certification in January 2006

[The transition to 2015 edition in Apr 2018] |

| ISO 14001 |

certification in January 2001

[The transition to 2015 edition in Apr 2018] |

|

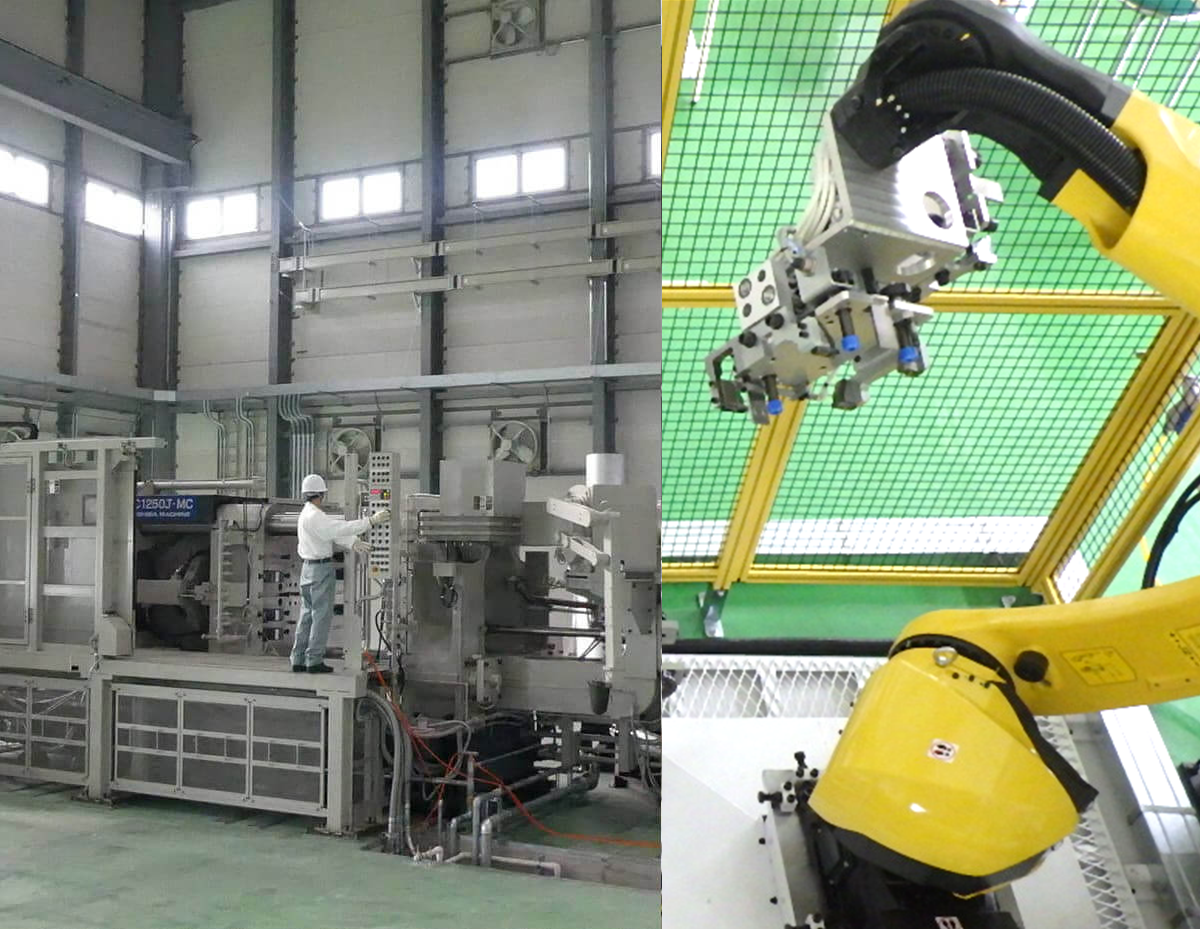

5-axis machining center / CNC tapping center 58

NC / vertical / horizontal milling machine, NC lathe,

multi-axis drilling machine, multi-axis tap machine,

surface grinding machine 11

Cleaning system (including automatic vacuum cleaning and drying system) 2